PV ribbon

Material Specification

Basic Material Copper Content: ≧ 99.90%

Base Copper Conductivity: ≧99% IACs

Tensile Strength: ≦ 25kgf/mm²

Elongation:≧25% (copper width < 3mm), ≧15% (copper width≧3mm)

Bare Copper Flat Wire Thickness Tolerances:±10% of the nominal thickness

Bare Copper Flat Wire Width Tolerances:±0.1mm

Soldering Specification

Solder Composition in wt%:

- Tin Lead: Sn60/Pb40(183-190°C); Sn62/Pb36/Ag2(179°C)

- Lead-Free: Sn96,5/Ag3/Cu0,5(219°C); Sn96,5/Ag3,5(221°C)

- Low Temp, Lead-Free: Sn/Bi Series(138-160°C); OO/Sn Series(115-150°C)

Thiskness of Single Coating Layer: 10-40 μm (depends on customer’s requirements)

Storage: 12 months from manufacturing date with unpackaging at room temperature

| Item | Copper Size | Coatings Alloy | Coat Thickness | Yield Strenght | Tensile Strenght | Elongation |

| Cell Ribbon | 0.6×0.20mm |

1.Sn63/Pb37 2.Sn62/Pb36/Ag2 3.Sn60/Pb40 4.Sn96.5/Ag3/Cu0.5 5.Sn96.5/Ag3.5 6.Sn42/Bi58 |

A:15±5µm B:20±5µm C:25±5µm D:30±5µm E:35±5µm F:40±5µm |

≤7Kgf/mm2 | ≤25Kgf/mm2 | ≥20Kgf/mm2 |

| 1.2×0.20mm | ||||||

| 1.5×0.20mm | ||||||

| 1.7×0.20mm | ||||||

| 2.0×0.20mm | ||||||

| Bus Ribbon | 5.0×0.30mm | N/A | ≥15Kgf/mm2 | |||

| 5.0×0.35mm |

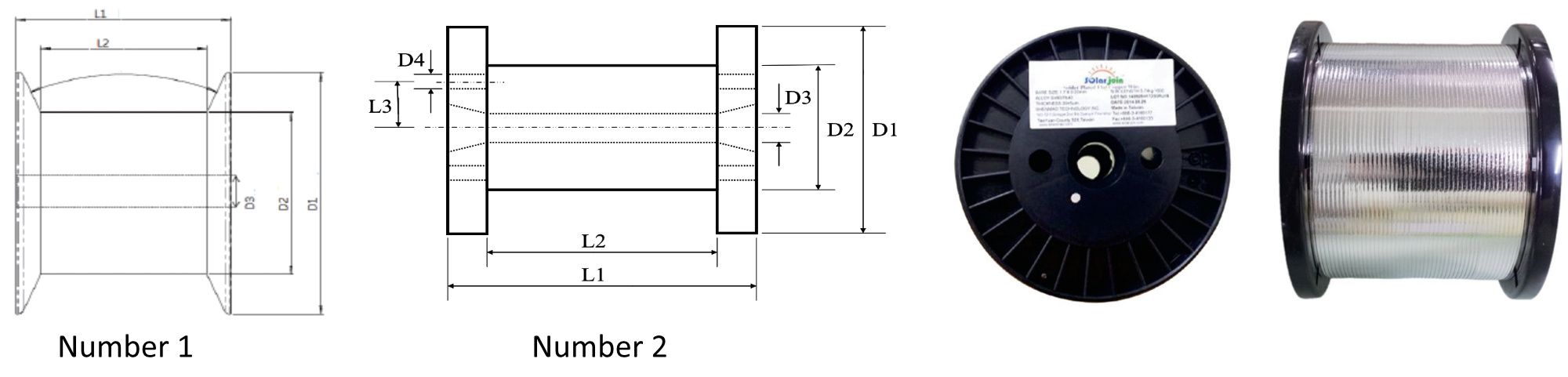

PV Ribbon Package Method

Spool Type

| Number | D1 (mm) |

D2 (mm) |

D3 (mm) |

L1 (mm) |

L2 (mm) |

Material |

| 1 | 152 | 102 | 20 | 122 | 94 | ABS/HIP |

| 2 | 160 | 90 | 22 | 160 | 85 | ABS/HIP |

Our Newsletter